Water contamination is the leading cause of catastrophic machinery failure. A Nuicon Moisture in Oil Sensor provides your first line of defense. By continuously monitoring Water Activity (aw) and Temperature, our sensors detect dissolved moisture in power transformers, turbines, and hydraulic systems long before free water forms and causes damage.

In insulating oil, moisture lowers dielectric strength, leading to dangerous arc flashes and outages.

Water accelerates oil oxidation and rusts components from the inside out.

Real-time data lets you switch to "Condition-Based Maintenance," changing oil filters only when necessary, not just on a schedule.

Every unit is factory-adjusted, with NABL-traceable calibration options available for critical audits.

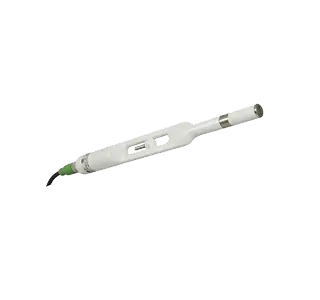

The expert choice for Power Transformers. Calculates ppm and handles high temperatures (180°C).

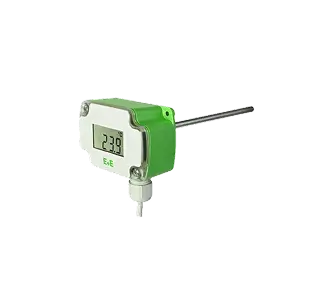

Features a metal housing and local display. Built for heavy industrial lubrication skids and steel mills.

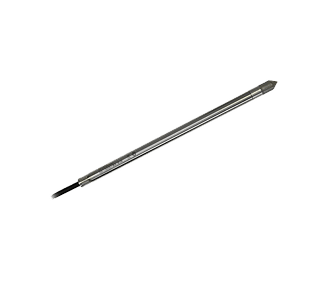

The miniature sensor for OEM Hydraulic Packs and gearboxes where space is tight.

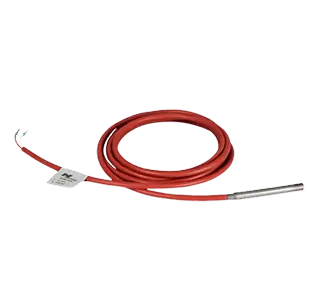

Dedicated temperature sensors for ducts, pipes, and outdoor walls.

Power Generation: Transformers and Turbine lubrication.

Marine & Shipping: Main engine lube oil and thruster hydraulics.

Manufacturing: Plastic injection molding and metal stamping presses.

Wind Energy: Remote monitoring of gearbox oil health.

We help you configure sensors for Mineral, Synthetic, or Ester oils.

NABL-traceable calibration to ensure your safety limits are accurate.

Fast troubleshooting and replacement stock from Bengaluru.

It continuously measures water contamination (ppm or % saturation) in compressor and refrigerant oils.

Water creates corrosive acids in the oil, which destroys internal components and leads to catastrophic compressor failure.

It’s an early warning system that detects moisture in real-time, preventing major breakdowns and costly repairs.

Continuous monitoring provides real-time protection and catches sudden leaks that periodic manual sampling can miss.

They are installed directly into the oil line of large equipment like industrial chillers and compressors.

Common sources include system leaks, improper servicing, or the breakdown of internal components.