Protect Your Equipment from Moisture, Rust, and Failure. Moisture is the #1 enemy of industrial machinery. In compressed air systems, “wet” air leads to rusted tools, frozen valves, and spoiled end-products. A reliable Dew Point Sensor is your only defense. Nuicon provides high-precision Dew Point Transmitters designed to monitor residual moisture in compressed air lines, plastic drying hoppers, and medical gases. Whether you are running a simple refrigeration dryer or a critical desiccant system down to -60°C, our sensors ensure your air meets strictly ISO 8573 purity standards.

Quickly verify paint thickness for used car assessments, repairs, and quality checks.

Ensure coating specifications are met on structural steel, railings, and metal fixtures.

Perform fast pass/fail checks on production lines and incoming parts.

Confirm coating thickness during application to prevent costly over- or under-application.

Best for Refrigeration Dryers (-20°C Td). Compact and cost-effective.

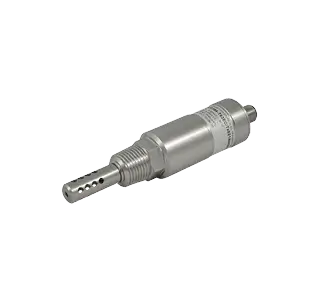

Best for Desiccant Dryers (-60°C Td). High precision and stainless steel body.

Complete solution with Display and Alarms for critical visual monitoring.

We don't just sell sensors; we help you select the right range (EE354 vs EE355) for your specific dryer.

We offer NABL-traceable calibration to keep your plant audit-ready.

We supply sampling cells, quick-disconnect couplings, and displays for a hassle-free installation.

It is the exact temperature at which air becomes saturated and condensation begins to form.

Use it in critical applications like data centers or compressed air lines where any condensation is unacceptable.

To prevent moisture from rusting pipes, damaging pneumatic tools, and contaminating end products.

It allows a control system to act before condensation forms, preventing corrosion and equipment failure.

Risks include equipment corrosion, product spoilage, and mold growth in critical environments.

Yes, meteorologists use it as an accurate indicator of how humid it actually feels.