Where air meets intelligence. This sleek sensor doesn’t just measure airflow, it empowers environments. From sterile labs to bustling factories, it captures the pulse of moving air with precision and converts it into clean, digital insight. Built to endure, designed to integrate, and calibrated for clarity, it’s the unsung hero behind smarter climate control and optimized ventilation

Quickly verify paint thickness for used car assessments, repairs, and quality checks.

Ensure coating specifications are met on structural steel, railings, and metal fixtures.

Perform fast pass/fail checks on production lines and incoming parts.

Confirm coating thickness during application to prevent costly over- or under-application.

Turning airflow into insight—precision monitoring with every breath

Ultra-low air velocity transmitter with compact design, ideal for HVAC and cleanrooms.

Hot-film air velocity sensor up to 20 m/s with flexible outputs for HVAC systems.

Air velocity and temperature transmitter with fast response for building automation.

High-precision airflow sensor up to 40 m/s, built for industrial and HVAC applications.

Measuring Range: 0.2 m/s up to 40 m/s (model dependent)

Accuracy: ±(0.2 m/s + 2–3% of reading)

Sensor Principle: Thermal hot‑film anemometer

Outputs: Analog (0–5 V / 0–10 V / 4–20 mA) or Digital (Modbus RTU)

Operating Temperature: –20 °C to +60 °C (probe), –10 °C to +50 °C (electronics)

Protection Class: IP65 housing for reliable use in harsh environments

Wide Range: Measures airflow from ultra‑low to high velocities with precision

Hot-Film Sensor: Ensures fast response and long-term stability

Compact Probe: Slim design allows easy duct or system installation

Flexible Outputs: Supports analog and digital signals for seamless integration

Durable Build: Resistant to dust and harsh industrial conditions

Temperature Compensation: Maintains accuracy across varying thermal environments

For Rough Surfaces, For High Precision, For Non-Metals and For Tight Spaces

A CO₂ sensor monitors carbon dioxide levels for safe and healthy air

Monitors moisture and heat for balanced indoor climate

Detects condensation risk for reliable system protection

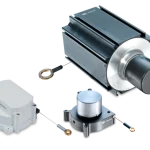

Collects data from multiple sensors for easy monitoring

Detects water in oil to protect equipment

Measures humidity and temperature for system integration

It measures the speed of air inside ducts or controlled spaces and sends that data to a control system.

To ensure the HVAC system is balanced and efficient, delivering the correct airflow to each room.

They are typically installed inside air ducts, VAV boxes, or critical environments like cleanrooms.

Yes, incorrect airflow readings can help diagnose blocked filters, fan issues, or faulty dampers.

It heats a thin wire; as air flows, it cools the wire. The power needed to keep it hot equals the air velocity.

They usually provide a standard 4-20mA or 0-10V analog signal compatible with any BMS.